Any Cad tool, for example Auto Cad or Corel Draw may be used for drawing the shape, as long as the file could be saved in the DXF component. CAD means Computer-aided Product. It is a modeling tool created to design curves and figures in 2 dimensional space (2D) or curves, surfaces and objects in three-dimensional space (3D). There are various CAD files construction business. More recommended ones include Instant Engineer 14, can easily be purchased online for few dollars, DesignCAD, AutoCAD and TurboCAD. Another Cad tool software package are DevFoam, that combines both the drawing and the G-Code technology. It is a simple application for cutting foam with a 4 Axis CNC exercise machine.

Go for lifts furnished with CNC Machining and Delrin ball bearings. You want value for all your money, so make yes you will lifts are made with quality and precision.

I have one associated with these “invisible jobs” that is seldom recognized, but universally valued. You see, typical likes with regards to their cell phone, computer, driving their car, playing CD’s, and generally enjoying the fruit of all our working hard.

Through 3D printing, a device will lie down very small layers of fabric down relating to layout. Sometimes the detail level is a small part of a millimeter. Think about this city being constructed from 3D printing documents and photos. Small buildings, stop signs, cars, and various landmarks are increasingly being made.25 millimeters at a time, all while retiring cnc machine xyz material for that ball which encompasses area. The end product will result in a ball with a miniature city inside of computer. This is very possible through 3D printing, others of manufacturing simply cant do this.

Next step is to convert the shape into G-Code. The G-Code is another name for your computerized tool by which we tell the machine what to and the right way to cut it. For the conversion one can use software with regard to example DeskCNC, DevCad or FoamWorks.

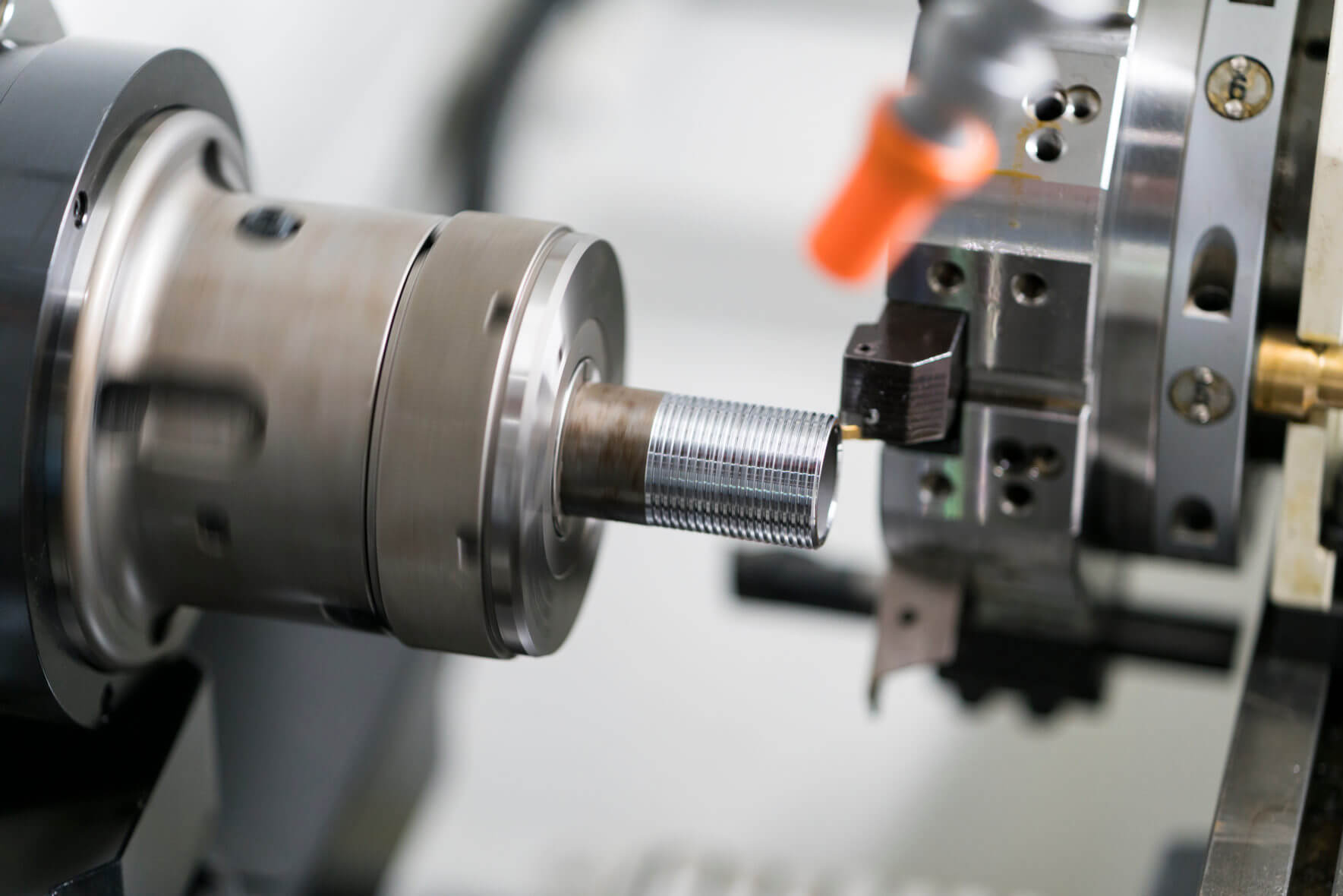

So, for the next month or two, the mold maker works along with machinists, apprentices, and other mold maker to fabricate all the shapes and pieces that comprise a finished mold. They must have to cut steel with special cutters on very sophisticated machinery prevented easily cost $150,000.00 just about.

While you’re waiting for your engineering renditions and working model, start thinking relating to your presentation package which it’s totally put together yourself. An appliance cover letter introducing yourself, your idea, your renditions as well as a picture of the working model is probably it.